Products Description

50L Home Alcohol Reflux Column Still

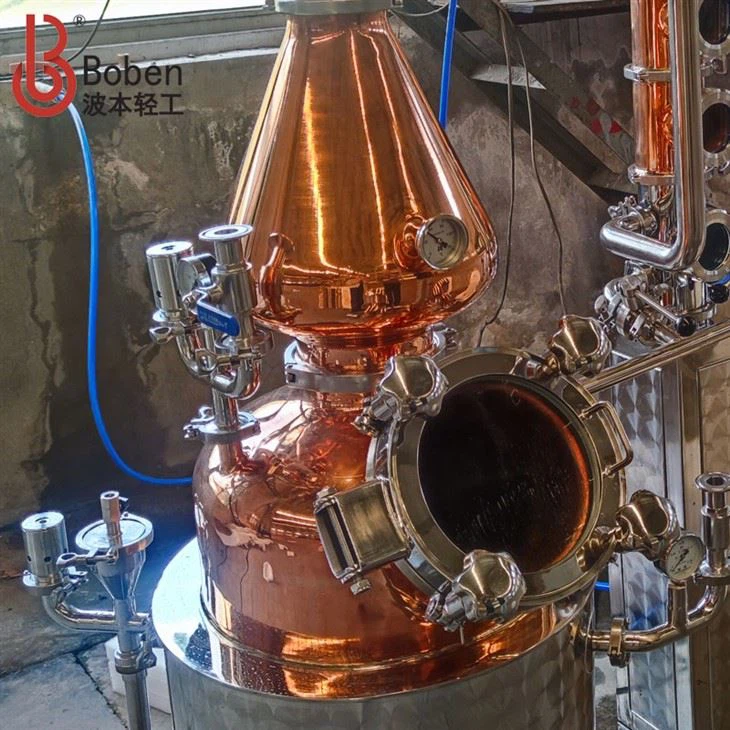

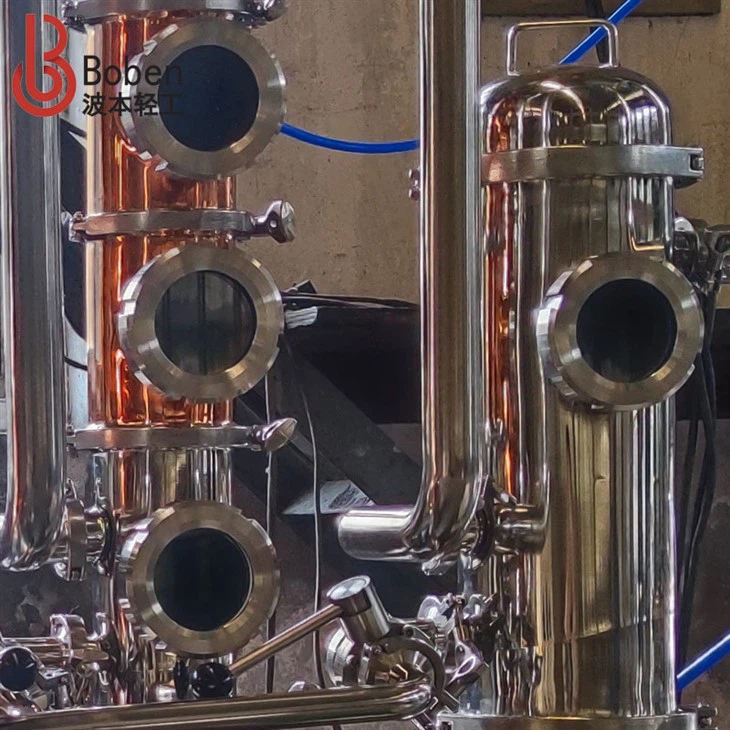

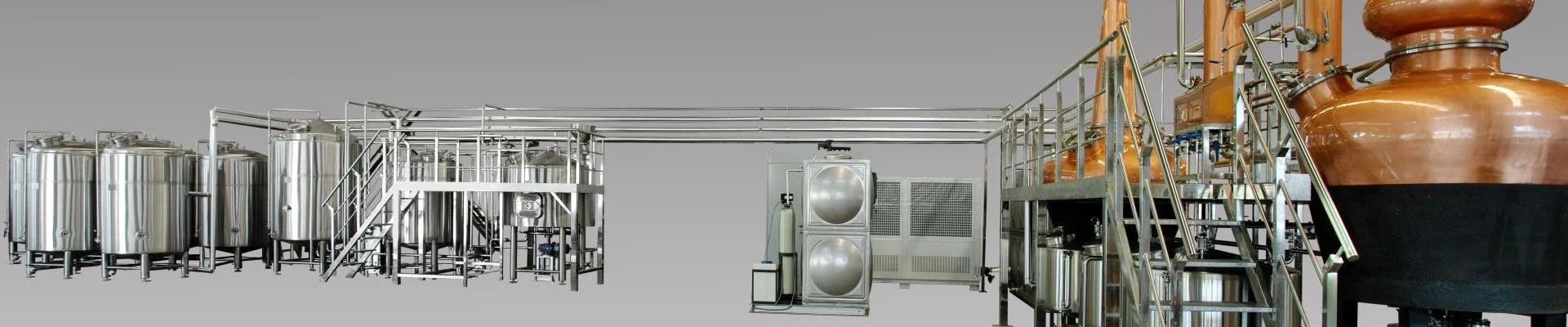

| Product Name | Column Reflux Still Whiskey Distillery Equipment |

| Material | SUS304/red copper |

| Parts | Boiler, Colunmn, Control Box, Dephlegmator, Condenser, Parrot Outlet, etc |

| Pot Working Size | 50L-5000L, can be customized for any sizes within container ship |

| Polishing | Mirror finish, sand finished |

| Heating | Electric/steam /gas powered |

| Usage: | Distilling various spirits: rum whisky gin vodka brandy etc |

| We can customize the equipment according to your requirements. | |

why choose boben

①We can customize the still according to customer's needs and budget.

②Boben is one of the largest direct R&D manufacturers of distillation machines in China.

We provide Whiskey, Vodka, Brandy, Rum, Gin, and essential oil making machines. Our engineers focus on this area for more than 15 years. The complete set of designs will be provided. Include equipment design and production line layout. Also, we offer installation and training services.

Our products pass the CE test.

contact us

Contact us freely to custom build your own distillery, please contact us:

Email: michael@bobendistillers.com

Web: www.bobendistillers.com

Whatsapp: +86 19157816531 (Mobile)

column still

A column still, also called a continuous still, patent still or Coffey still, is a variety of still consisting of two columns. Column stills can produce rectified spirit (95% ABV).

Description

The first column (called the analyzer) in a column still has steam rising and wash descending through several levels.The second column (called the rectifier) carries the alcohol from the wash, where it circulates until it can condense at the required strength.

A column still is an example of a fractional distillation, in that it yields a narrow fraction of the distillable components. This technique is frequently employed in chemical synthesis; in this case, the component of the still responsible for the separation is a fractionating column.

A continuous still can, as its name suggests, sustain a constant process of distillation. This, along with the ability to produce a higher concentration of alcohol in the final distillate, is its main advantage over a pot still, which can only work in batches. Continuous stills are charged with preheated feed liquor at some point in the column. Heat (usually in the form of steam) is supplied to the base of the column. Stripped (approximately alcohol-free) liquid is drawn off at the base, while alcoholic spirits are condensed after migrating to the top of the column.

Column stills are frequently used in the production of grain whisky and are the most commonly used type of still in the production of bourbon and other American whiskeys. Distillation by column still is the traditional method for production of Armagnac, although distillation by pot still is allowed. The use of column stills for the distillation of Cognac is forbidden, although they may be used for other types of brandy, likewise malt Scotch Whiskies must be distilled in a pot still. Distillation by column stills is permitted for Calvados AOC and Calvados Domfrontais. Calvados Pays d'Auge AOC is required to be distilled by pot still.

Difference between pot still and column still

Column stills behave like a series of single pot stills, formed in a long vertical tube. The tube is filled with either porous packing or bubble plates. The rising vapour, which is low in alcohol, starts to condense in the cooler, higher level of the column. The temperature of each successively higher stage is slightly lower than the previous stage, so the vapour in equilibrium with the liquid at each stage is progressively more enriched with alcohol. Whereas a single pot still charged with wine might yield a vapour enriched to 40–50% alcohol, a column still can achieve a vapour alcohol content of 96%; an azeotropic mixture of alcohol and water. Further enrichment is only possible by absorbing the remaining water using other means, such as hydrophilic chemicals or azeotropic distillation, or a column of 3A molecular sieves, like 3A zeolite.